USA: 1-800-338-3568 | CANADA: 1-866-591-5594

When it Comes to Vinyl Decking, Does Thicker Mean Better?

If you are considering sheet vinyl for your deck waterproofing solution, you may be presented with the idea that a higher vinyl membrane thickness is better protection. For reliable waterproofing, that is not accurate at all. Waterproof is waterproof.

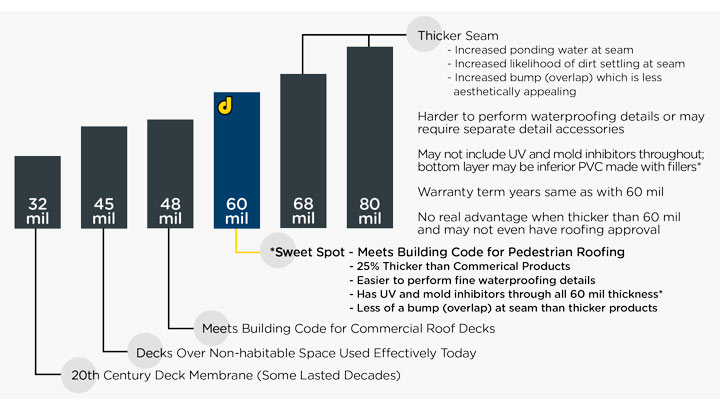

With vinyl decking, it is best to refer to building code requirements as your guideline because thicker does not mean better. If your deck is over 2 ft. off the ground and sheds water, by the building code it requires a roofing membrane. If your deck is intended for pedestrian traffic, you must also ensure it is approved for walking on (light pedestrian traffic).

60 mil vinyl is the recognized industry standard for a walkable roof membrane. Anything over a 60 mil thickness on roof decks does not give you any further waterproof protection. It is either waterproof or it is not.

When Duradek first started waterproofing decks and balconies, the thickness of the PVC membrane used was only 20 mil, and those decks lasted for several years. Today, the thickness of a vinyl sheet membrane for decks not requiring building permits is more than double that at 45 mil.

Is a Thicker Vinyl Better for A Roof Deck?

Pedestrian roof decks have a Building Code requirement of 60 mils. That is already 25% thicker than a large commercial grade roofing requirement (48 mils thick). The only real difference in these applications is that commercial flat roofs are not intended to have foot traffic beyond service requirements. Anything over and above the required 60 mil thickness on pedestrian decks situated overrated or habitable space does not give you any further waterproof protection. The real difference lies in the installation. In fact, a thicker vinyl can come with disadvantages.

Download: Does Thicker Vinyl Really Mean Better? (pdf)

How Vinyl Thickness Effects Installation

Sheet vinyl comes in rolls, typically between 60-72 inches wide. It is rolled out the length of the deck and installed by adhesion to the deck substrate and by heat-welding the seams where the edges of vinyl meet. The seams are usually ¾” to an inch wide, and it is this area of overlap for heat-welding the vinyl seams that an increase in thickness can really be a disadvantage.

Even a 10% difference can be noticeable and make your deck susceptible to things like trapped, ponding water which is something to be avoided with vinyl deck surfaces. Some commercial projects prefer to use an 80 mil vinyl, which is far above building code requirements but does not give any real added advantage. In fact, that 20 mil difference doubled up at the seam makes a 40 mil difference which is quite noticeable visually as well as by unexpected disadvantages.

Some consideration should be paid to the disadvantages that come with a deck vinyl that exceeds building code thickness.

- Trapped, ponded water.

- Potential tripping hazard.

- Easier to catch seam on a snow shovel.

- Difficulties at installation with the fine detailing and handling.

There are actually a number of existing vinyl installations on sundecks from over 30 years ago using 24-32 mil vinyl that are still performing the waterproofing function today. Just a couple of years ago, we pulled up the vinyl from a 32-year-old deck that had 32 mil Duradek on it. The plywood, after 32 years, was in perfect shape and was used again as the substrate under a new Duradek vinyl membrane.

So for your project, if you want the advantages of a low-maintenance deck vinyl on an elevated deck, balcony, or roof deck, remember that exceeding the building code requirements above 60 mil only provides a thicker seam and no additional waterproof protection.

What is More Important Than Thickness in a Waterproof Vinyl Membrane?

- Quality of the Vinyl

- Product Warranty

- Building Code Requirements

- Installation

Vinyl Product Quality

Some vinyl products are made up of layers and only include quality elements like UV stabilizers and mold inhibitors in the top layer. The bottom layer can be made of inferior filler materials. This could make them more susceptible to premature deterioration and appearance issues.

North American manufactured Duradek is produced using only high-quality PVC with UV stabilizers and mold and mildew inhibitors throughout the entire 60 mil thickness. This advantage allows Duradek to be one of the only vinyl options that perform well under any condition.

Warranty Coverage of Vinyl Membranes

The thickness of the vinyl has nothing to do with how much protection the warranty provides. Building product warranties can be misleading if you are only to look at the overall years of coverage as it is the terms during the coverage period that count.

Duradek presents one of the only vinyl membrane warranties that is openly available and offers three tiers of protection: Manufacturer’s Product Performance, Appearance, and Workmanship. Duradek is the only warranty to date that we have seen that is openly transferable to new owners.

Does the Vinyl Membrane Meet Building Code Requirements

As mentioned at the beginning of this article, if the deck is elevated 2 ft. or more and sheds water, it requires a roofing membrane to satisfy building code requirements. If it is subject to foot traffic, it also requires a pedestrian traffic coating.

Duradek’s 60 mil vinyl meets building code as both a pedestrian traffic coating and a classified roofing membrane. Many 68 mil vinyl products to not comply to building code requirements as a classified roofing membrane.

Installation of a Waterproof Vinyl Membrane

The reliable protection of vinyl decking is due in large part to the skilled installation techniques of your contractor, and thicker vinyl makes it more difficult to perform the critical details for water-tight protection.

With some of the thicker vinyl options, the critical waterproofing details cannot even be performed on the job site as the product does not have the malleability to form the shapes required. These types of vinyl require the separate purchase of pre-manufactured detail accessories.

Duradek understands that no matter how reliably a vinyl membrane product is manufactured if it is not installed by skilled applicators using reliable techniques it has a likelihood of waterproofing issues down the road. That is why Duradek is only available through a network of trained and authorized applicators and is not available as a DIY product.

So, is Thicker Really Better for a Vinyl Roof Deck?

Download: Does Thicker Vinyl Really Mean Better? (pdf)

If you’ve read this far, you already know the answer to that. But check out this short video clip where Duradek president, John Ogilvie, answers the question, “Is thicker really better for a vinyl roof deck?”:

Remember, since installation skills are so critical, Duradek is available only through one of our trained and authorized Duradek dealers.

To talk to an experienced Duradek expert near you, visit our Find A Dealer page or contact us directly for a referral at duradek@duradek.com.