USA: 1-800-338-3568 | CANADA: 1-866-591-5594

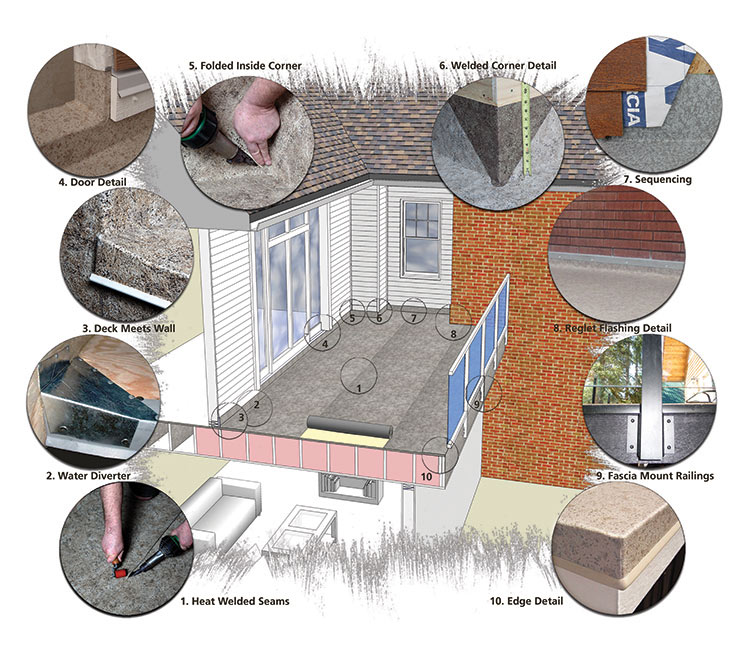

How to Ensure Reliable Deck Waterproofing Details

When investing in a deck addition or upgrade, one of the most difficult decisions is selecting a contractor that you can be confident will do competent work. It’s a big investment, so you want to be sure the job is done right the first time. That means someone who thoroughly understands deck waterproofing details. This is not the time to turn to your typical DIY friend. Talk to your contractor openly about your project, ask to see some of their jobs, and gather references.

Good, Better and Best Deck Waterproofing Details

There are Good, Better, and Best methods of achieving the desired result for your project. The methods your contractor chooses can be influenced by building code requirements, your budget restrictions, or your insistence (it is your project, after all). You can be confident that your professional Duradek contractor will always recommend the best methods to ensure reliable waterproof protection and that you receive the best results for your deck.

Deck Prep Details for Waterproof Vinyl

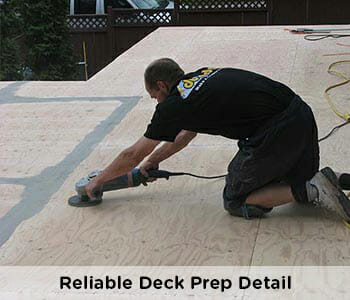

Recommended

A properly prepared substrate must be a smooth, flat surface with consideration to moisture content, fill, gaps, and other details.

See our Substrate Recommendations.

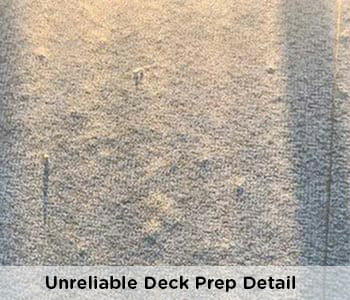

Not Recommended

Inadequate substrate preparation can result in uneven finished surfaces like ridges at the plywood seam, bumps, bubbles, and more that can telegraph through the vinyl.

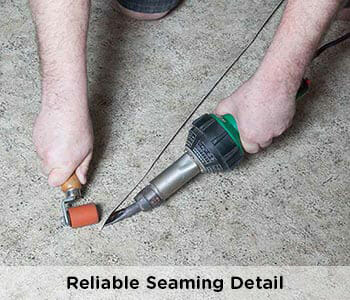

Seaming Details for Waterproof Vinyl

Recommended

Duradek waterproofing is a 3-weld system. We recommend a 3/4″ seam overlap, back welded, then the main weld, and complete the seam with a cap weld.

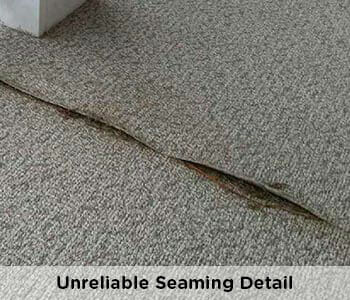

Not Recommended

Using seam tape, seam sealer, not enough seam overlap, or other poor securement techniques are not recommended and can lead to seams gaping and splitting, destroying the system’s waterproofing integrity.

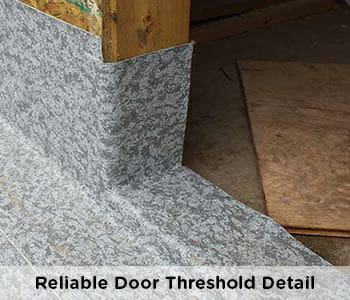

Door Sill for Waterproofing Details

Recommended

Duradek recommends removing the door and running vinyl into the door sill to create a watertight door flashing ensuring complete waterproof protection. See Detail Drawings IS-03, IS-04, and IS-09.

Not Recommended

Cutting vinyl around the door sill is not recommended and cannot be relied on to be watertight.

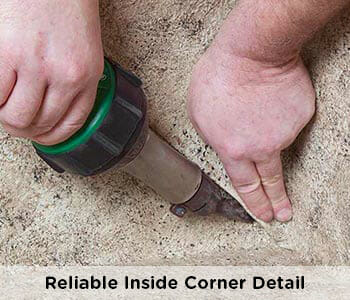

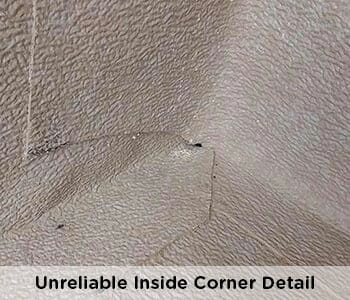

Inside Corner Deck Waterproofing Details

Recommended

Duradek recommends folding into a dog ear and fusing vinyl at inside corners without the use of relief cuts. Must extend up all at least 6”.

Not Recommended

Relief cuts are not recommended as they are an unnecessary risk to waterproofing integrity. It also leaves a pinhole at the corner.

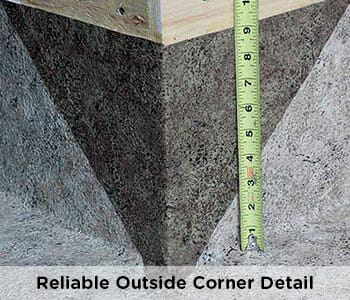

Outside Corner Deck Waterproofing Details

Recommended

Duradek recommends using a watertight welded triangle patch on outside corners. Must extend up all at least 6″.

(Image example shows two colors for demonstration only.)

Not Recommended

Simply wrapping corners with vinyl is not recommended and cannot be relied on to be watertight as it leaves a pinhole at the corner.

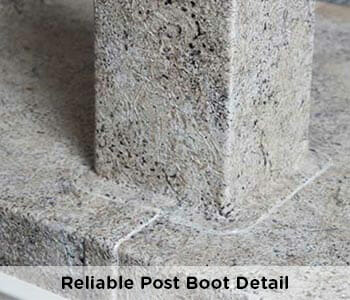

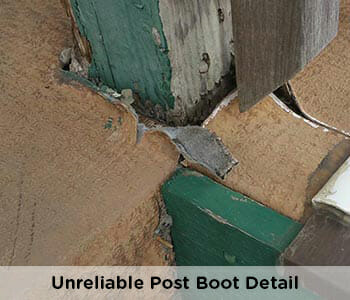

Post Boot Deck Waterproofing Details

Recommended

Duradek recommends wrapping the vinyl up the post a minimum 6″, then overlapping a vapor barrier by minimum 2″, and finish with cladding with a minimum 2” clearance from deck surface (L-trim optional).

See Detail Drawing P-01.

Not Recommended

Failure to extend the membrane up the post and simply caulking the edge of the vinyl to the base of the post is not recommended.

Drip & PVC Clip Details for Waterproof Decks

Recommended

Duradek recommends leaving 3/4″ of vinyl to fully wrap the flashing drip edge before installing the Clip.

See Detail Drawing OS-01.

Not Recommended

Cutting the vinyl flush with the bottom of the flashing, or cutting ‘tabs’ can lead to vinyl receding beyond where the clip covers due to shrinkage.

L-Trim Details for Waterproof Decks

Recommended

Duradek recommends wrapping the edge of the deck with membrane and installing L-Trim over top with butyl tape and fasteners to secure vinyl.

See Detail Drawing OS-02.

Not Recommended

Leaving vinyl glued down with no mechanical fastening is not recommended.

PVC Coated Drip Flashing Details

Recommended

Duradek recommends welding vinyl to PVC coated flashing. Flashing joints are to be covered with PVC Tape.

See Detail Drawing OS-03.

Not Recommended

Do not allow contact adhesive or floor leveler on the last 3/4″ surface of the PVC coated flashing where you will be welding. Cutting vinyl uneven with drip edge and leaving unsecured is not recommended.

Duradek Applicators Do Deck Waterproofing Details Right the First Time By:

- Ensuring adequate deck slope

- Ensuring correct plywood for the substrate

- Using only compatible fillers, adhesives, and accessories

- Removal of pre-existing doors (where possible)

- Removal of cladding or stucco (where possible)

- Advising of compatible building papers and products

- Proper installation of drains and scuppers

- Waterproofing posts and columns like walls

Duradek has a collection of over 50 Detail Drawings for free download. For designers and specifiers, BIM models can be accessed on CAD details.

Remember, the most important detail in the specialty trade of vinyl deck waterproofing is the skill of the decking contractor. Duradek applicators are trained in waterproofing details, deck design, and building code requirements to ensure the job is done right the first time. Contact a Duradek professional near you for a free estimate.

Discover the Duradek Difference.

Interested in staying informed on the world of PVC membrane decks and flat roof decks? Get industry insights, invites, and the latest news from Duradek on our limited distribution e-news.