USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Installation Details

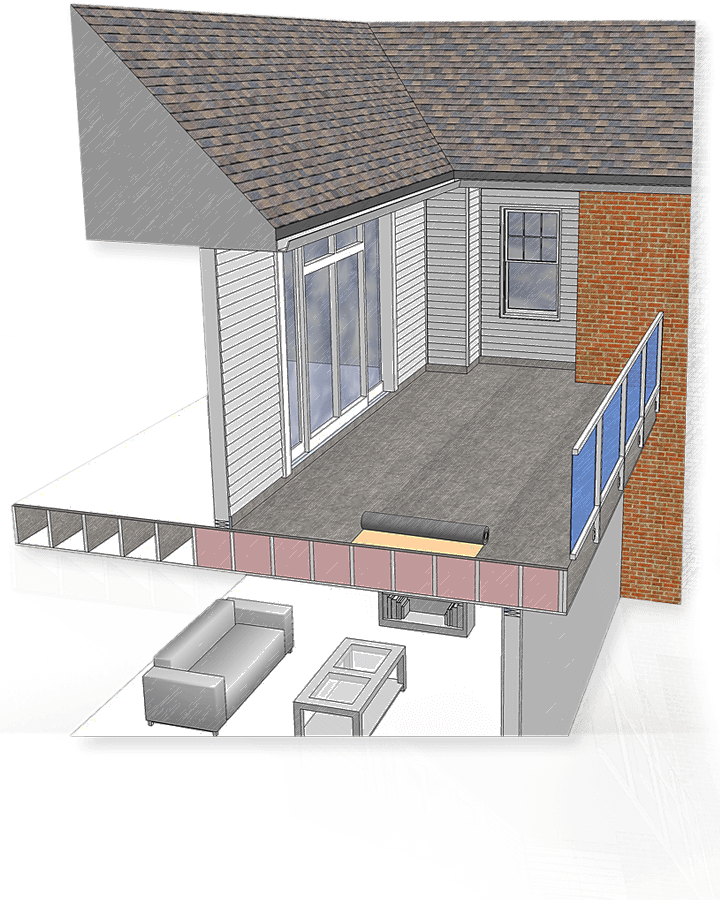

Vinyl deck installation details developed through Duradek’s 50+ years of waterproofing experience come with unsurpassed installation techniques for moisture management. The integration of the membrane into the building envelope brings complete waterproof assurance.