USA: 1-800-338-3568 | CANADA: 1-866-591-5594

What You Need to Know to Avoid Leaky Tile Decks: Part 1 – Getting Familiar with Tiledek

Getting Familiar with Tiledek

We’d like to introduce you to a way to avoid leaky tile decks. They can be a huge source of frustration for many builders and homeowners throughout North America, particularly when the tile deck is above living space. However, the methods that have been used in the past without much success are no longer the only options.

Duradek Ultra Tiledek was manufactured specifically to provide waterproofing peace of mind underneath exterior tile roof decks. It is the only roofing membrane specifically produced for waterproofing under outdoor tile AND that comes with a 10-year warranty that guarantees waterproof protection.

This article is part 1 in a 4-part series in a basic Q & A format to help you get acquainted with the specifics of Tiledek and waterproofing under exterior tile.

In part one, we will familiarize you with Tiledek and why it is the essential waterproofing component for outdoor tile projects.

What is Tiledek

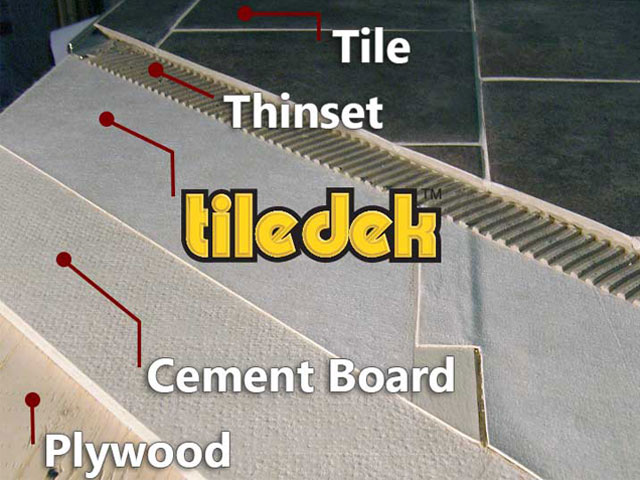

Duradek Ultra Tiledek is a 60 mil thick, PVC roofing membrane similar to Duradek “Ultra”. It is designed to have outdoor porcelain tile or slate installed over top of it with a thinset mortar bond coat. Lightweight concrete or cementitious finishes can also be installed over it. From here on we will just refer to the overlay products as ‘tile’.

A fabric has been laminated to the topside of the roofing membrane to provide for a strong physical “grab” by the thinset mortar. Tiledek comes in rolls 6 feet wide and 75 feet long. Tiledek is only available as a “professionally installed waterproofing system” through the network of trained Duradek applicating contractors all over North America.

Is an outdoor tile deck application waterproof by itself?

Absolutely not! It is absolutely certain that water will get under the tile. That is precisely why there are so many problems with outdoor tile decks. People THINK and are even misled to believe that a tile installation is waterproof and therefore they don’t pay too much attention to the proper waterproof treatment underneath. The failures are often waterproofing failures where leaks that have been happening undiscovered for years eventually cause rot requiring major renovation work. Not only does the structure need replacement work, but the tile application must also be torn up to get at it.

The water will most likely enter through cracked grout joints or on the perimeters. If the tile cracks, water will enter. If the deck is in a cold climate, the moisture freezes and expands which may cause tiles to erupt.

A failure in the tile installation doesn’t mean the waterproofing system has failed. If the membrane is intact and performing its function of keeping the water out, replacing a cracked or erupted tile or a cracked grout joint is relatively easy and inexpensive.

What are Tiledek’s credentials?

Here’s how Tiledek has been tested to prove it can help you avoid leaky tile decks

Tiledek is a variation of Duradek Ultra, the first PVC walking roof deck material on the market. Duradek Ultra has been installed for over 35 years and has proven itself in all climatic regions of North America.

Quality Auditing Institute Ltd.(QAI), an independent testing, inspection, and certification agency, evaluated the Tiledek membrane (Evaluation Report T731-4), and based on this evaluation determined that Tiledek is considered compliant to the following criteria:

-

- ICC-ES: Tiledek meets the requirements of ICC-ES AC39 “Acceptance Criteria for Walking Decks” and ICC-ES AC75 “Acceptance Criteria for Membrane Roof Covering Systems” as a roofing membrane when installed in accordance with the IBC 2009 or IRC 2009 and the manufacturer’s installation instructions.

- CAN/CGSB 37.54: Tiledek meets the requirements for conformance to the materials standard of CAN/CGSB-37.54-95 “Polyvinyl Chloride Roofing and Waterproofing Membrane” classified as a Type 3, Class A membrane.

- Class “A” Fire Rating: Tiledek is considered to have a Class “A” rating when tested to ULC-S107 “Methods of Fire Tests of Roof Coverings” and ASTM E-108 “Standard Test Methods for Fire Tests of Roof Coverings” (when installed on and covered by non-combustible building components).

- ASTM C627: Tiledek meets the requirements of the standard test method for evaluating ceramic floor installation using the Robinson-type floor tester. Test Report #UFT 2008-008, #UFT 2008-009, #UFT 2008-010

Test conducted by Terrazzo, Tile & Marble Association of Canada (TTMAC). - ANSI A118.10: Tiledek meets the requirements of the ANSI specification for load bearing, bonded, waterproof membranes for thin-set ceramic tile and dimension stone installations. Test Report #TCNA-428-10

Test conducted by the Tile Council of North America (TCNA).

Tiledek Techtalk #108 provides a summary of Tiledek testing and approvals in pdf format.

Avoid Leaky Tile Decks with a Great Waterproofing Warranty

What is the warranty with Tiledek?

Tiledek is covered with the same waterproof warranty as Duradek Ultra – 10 years. See the sample Tiledek warranty on the Duradek website for the specific terms and conditions.

How is tile usually installed on decks and balconies?

There are two distinct methods of installing tile in waterproof applications: thickset (using a 1-½ inch “dry mud bed”) and thinset (using a ¼ inch acrylic modified mortar).

Thickset

Thickbed installations are based on the traditional method of packing a mortar bed over a surface before installing the tile. The tile is adhered to the mortar bed either while the mortar bed is green (just beginning to dry) or after the mortar bed has cured. The mortar bed may be reinforced with wire and either set over a cleavage membrane (that allows the mortar bed to “float” free of the substrate) or bonded to the substrate – hence the use of the terms “floating mortar bed” or “bonded mortar bed”. For wall applications, metal lath is mechanically anchored to the substrate and the mortar locks into the metal lath as it cures. The terms thick-bed installation, mortar bed installation, and thickset installation are synonymous.

The thickset method is more likely to be used where the tile is thick and irregular in order to achieve a flat walking surface.

Thinset

Thinset mortar is a blend of cement, very finely graded sand, and a water retention compound that allows the cement to properly hydrate. Tile set by the thinset method is adhered to the substrate with a thin layer of “thinset” mortar. This type of cement is designed to adhere well in a thin layer – typically not greater than 3/16th thick. For example, a 3/8″ notch trowel will produce a 3/16th-inch thick coating after the tiles are pressed into the cement. While very minor adjustments in height can be made, this method is not appropriate for adjusting the level of flatness of a surface – rather the tile will follow the plane of the substrate. Only “Gauged” tiles (with similar thickness) should be used in thinset mortar applications.

Medium-set

Medium-set mortars can be used to adjust for slightly larger variations in the substrate than can be accommodated with thinset mortar. They are also used with large, heavy, thick or “ungauged” (varying thickness) tiles, where a thicker setting bed and a coarser aggregate may be required to achieve a flat installation and to support the weight of the tile while the cement is curing.

Summary

Now that you are more familiar with Tiledek and the types of outdoor tile installation methods, be sure to check back next week for part 2 in this series –“ What You Need to Know to Avoid Leaky Tile Decks with Tiledek Waterproof Membrane: Part 2 – The Alternatives”.

In the meantime, you may like more detailed information from the trained and authorized Tiledek installer in your area.