USA: 1-800-338-3568 | CANADA: 1-866-591-5594

45 Vinyl Membrane Detail Drawings for Decks after 45 Years

Vinyl membrane detail drawings for decks can help AEC professionals easily incorporate waterproof outdoor living space into their designs.

Installation details for vinyl decks are a critical component of successful waterproofing. Especially when it comes to waterproofing flat roof decks over living space, reliable waterproofing depends on more than a high-quality product. The actual performance is all in the details and the skills of the installing contractor.

Since 1974, over 150 million square feet of Duradek vinyl membranes have been installed. With that much experience with a niche product and specialty application on decks over living space, Duradek has firmly established itself as the leader in the vinyl decking industry.

Our “roofing grade” details meet industry and government standards but more importantly have me the test of time.

In honor of 45 years in business, here are 45 of our most popular detail drawings for specifying and installing Duradek vinyl membranes.

45 Top Vinyl Membrane Detail Drawings for Decks

Duradek Vinyl Membrane Detail Drawings for Decks: Outside Perimeters

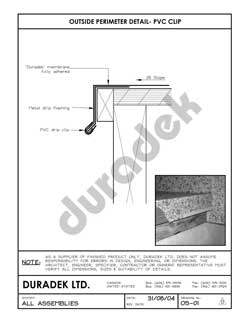

Outside Perimeter Detail OS-01 – PVC Clip: a popular perimeter detail that clips vinyl in place around metal drip flashing.

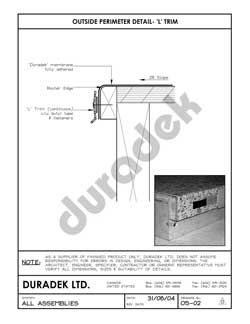

Outside Perimeter Detail OS-02 – “L” Trim: a mechanically fastened color matched aluminum edge detail.

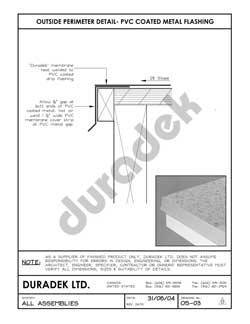

Outside Perimeter Detail OS-03 – PVC Coated Metal Flashing: perimeter detail that allows the surface membrane to be heat welded directly to the drip flashing.

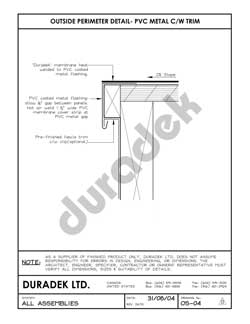

Outside Perimeter Detail OS-04 – PVC Metal C/W Trim: fully adhered PVC membrane heat welded to PVC coated metal flashing with optional fascia trim.

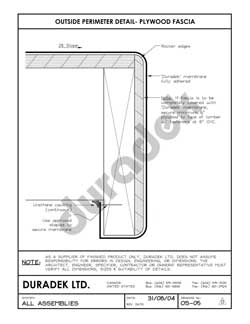

Outside Perimeter Detail OS-05 – Plywood Fascia: fully wrapping and adhering the membrane over a plywood fascia.

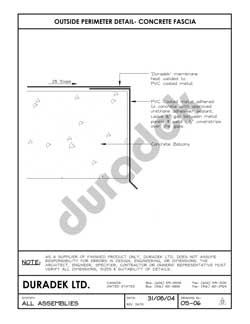

Outside Perimeter Detail OS-06 – Concrete Fascia: application of vinyl membrane on pvc coated metal sheet adhered to concrete fascia.

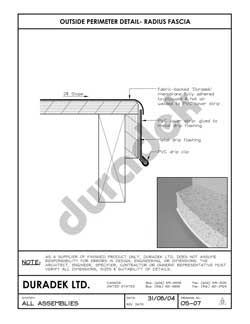

Outside Perimeter Detail OS-07 – Radius Fascia: covering curved fascia with use of heat welding to pvc cover strips on metal drip flashing.

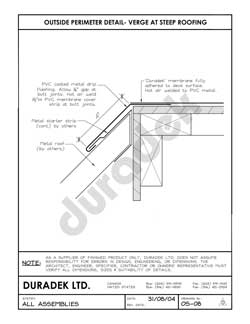

Outside Perimeter Detail OS-08 – Verge at Steep Roofing: PVC membrane fully adhered and heat welded to PVC metal drip flashing with an 1/8″ gap at butt joints.

Outside Perimeter Detail OS-09 – Deck/Wall Intersection: creating a water-tight barrier at the deck to wall intersection with membrane extension along wall and positive overlap with building sheathing paper.

Outside Perimeter Detail OS-10 – Water Diverters: an optional detail for the use of corner, return or mid-span diverters between substrate and membrane.

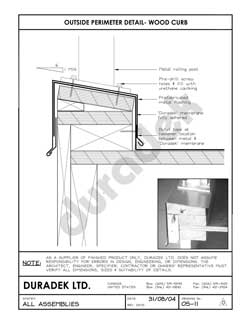

Outside Perimeter Detail OS-11 – Wood Curb: application of membrane over metal flashing on a wood curb to support railings.

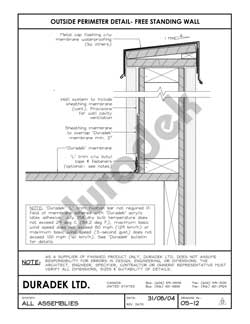

Outside Perimeter Detail OS-12 – Free Standing Wall: membrane vertically run up wall with a min. 2″ sheathing membrane overlap and optional L-trim fixation bar.

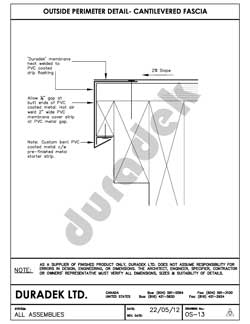

Outside Perimeter Detail OS-13 – Cantilevered Fascia: heat welded membrane to custom bent PVC coated flashing.

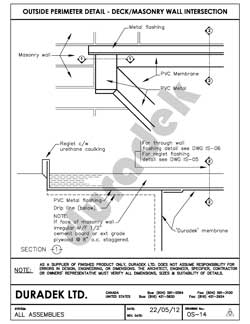

Outside Perimeter Detail OS-14 – Deck Masonry Wall Intersection: use of PVC metal flashing to heat weld PVC membrane to masonry wall at outside perimeter.

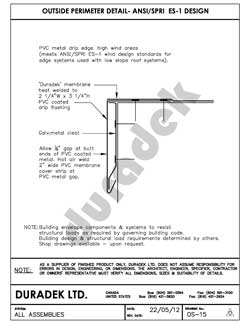

Outside Perimeter Detail OS-15 – ANSI/SPRI ES-1 Design: membrane heat welded to PVC coated drip flashing over galvanized metal cleat – this detail is required to meet Florida building code.

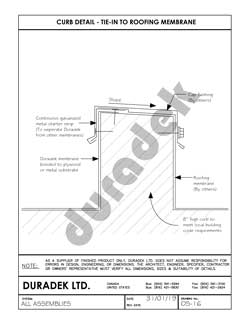

Outside Perimeter Detail OS-16 – Curb Tie-In to Membrane: vinyl membrane bonded to substrate with galvanized metal strip to separate from other roofing membranes.

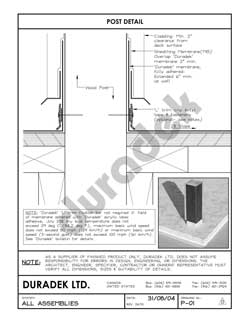

Post Detail P-01: PVC membrane fully adhered to post and overlapped with sheathing membrane and covered with cladding.

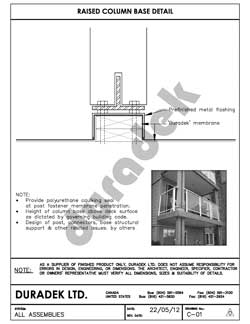

Column Detail C-01: membrane wrapped over column base and covered with pre-finished metal flashing.

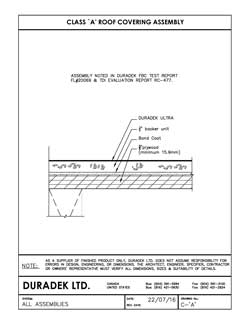

Class ‘A’ Roof Covering Assembly C-A: membrane adhered to backer unit bonded over plywood to achieve class A fire rating.

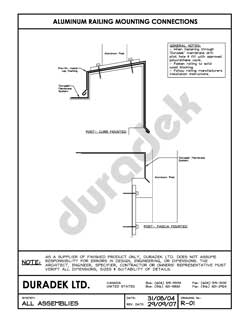

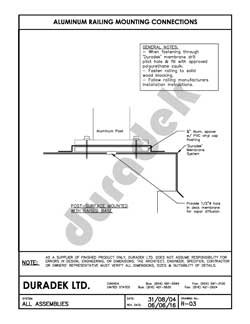

Aluminum Railing Curb or Fascia Mounted R-01: two variations of railing mounting – fascia or curb mounted.

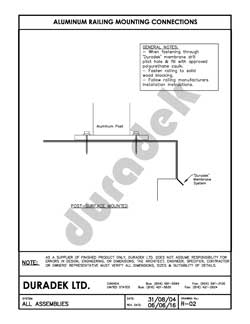

Aluminum Railing Surface Mounted R-02: surface mounted railing requiring polyurethane caulk.

Aluminum Railing Surface Mounted – With Raised Base Plate R-03: railing mounted on raised base plate wrapped with membrane with allowance for vapor diffusion.

Duradek Vinyl Membrane Detail Drawings for Decks – Inside Perimeters

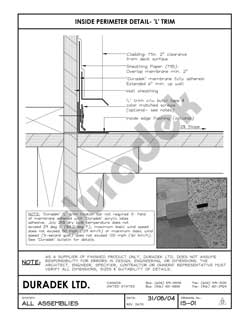

Inside Perimeter Detail IS-01 – ‘L’-Trim: optional detail where membrane is adhered over L-trim fixation bar and wall sheathing a minimum of 6″ up wall sheathing and overlapped by sheathing paper a minimum of 2″ with cladding a minimum of 2″ clearance from deck surface.

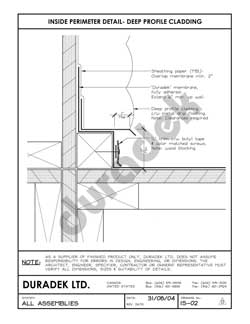

Inside Perimeter Detail IS-02 – Deep Profile Cladding: PVC membrane is fully adhered to surface and up wall minimum 6″ and overlapped by sheathing paper a minimum of 2″ behind deep profile cladding with a 1″ clearance of metal drip flashing.

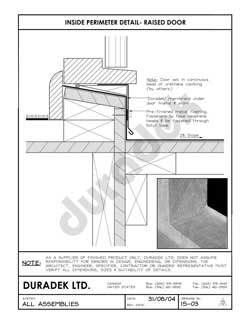

Inside Perimeter Detail IS-03 – Raised Door: PVC membrane adhered under door frame and shim with pre-finished metal flashing fastened through butyl tape.

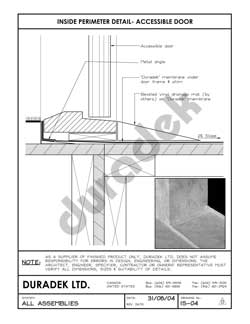

Inside Perimeter Detail IS-04 – Accessible Door: PVC membrane adhered under door fame and shim with beveled vinyl drainage mat.

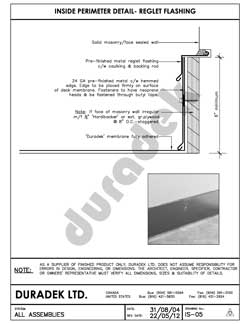

Inside Perimeter Detail IS-05 – Reglet Flashing: Metal reglet flashing detail for solid masonry walls.

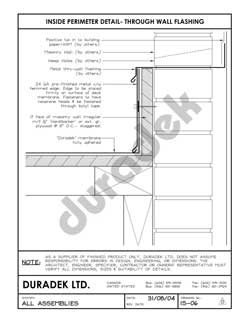

Inside Perimeter Detail IS-06 – Through Wall Flashing: through wall flashing on new construction with tie in to building paper behind masonry wall.

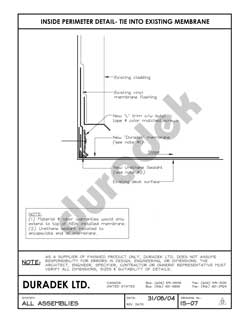

Inside Perimeter Detail IS-07 – Tie Into Existing Membrane: tie in to existing membrane where existing cladding cannot be removed.

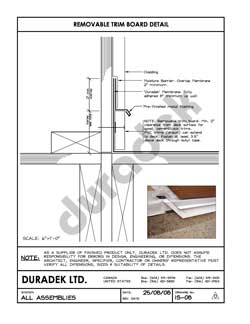

Inside Perimeter Detail IS-08 – Removable Trim Board Detail: use of removable trim board for ease of replacement where membrane is overlapped by moisture barrier behind cladding.

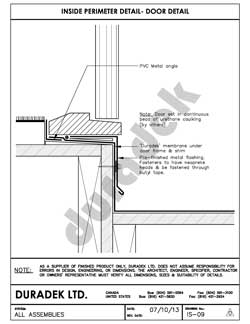

Inside Perimeter Detail IS-09 – Door Detail: PVC membrane is adhered under door frame and shim and secured with metal flashing fastened through butyl tape.

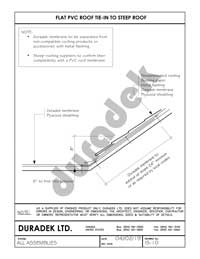

Inside Perimeter Detail IS-10 – Tie-In to Steep Roof: tie in PVC membrane from flat roof deck to shingled steep roof.

Duradek Vinyl Membrane Detail Drawings for Decks – Over Non-Habitable Living Space (Not Governed by Building Codes)

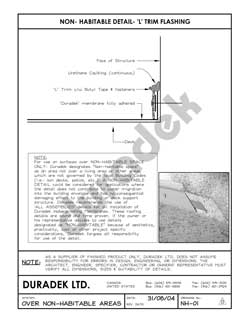

Non-habitable NH-01 – “L” Trim Flashing: securing PVC membrane to inside perimeter when over non-habitable space.

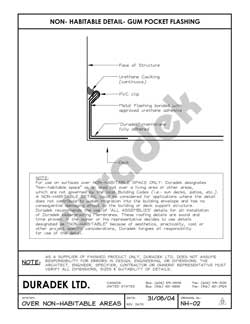

Non-habitable NH-02 – Gum Pocket Flashing: use of PVC clip over metal flashing and continuous urethane caulking over non-habitable space.

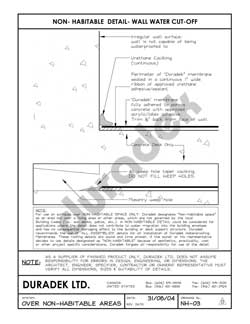

Non-habitable NH-03 – Wall Water Cut-off: Inside perimeter detail for PVC membrane on concrete substrate over non-habitable space where wall is not capable of being waterproofed to.

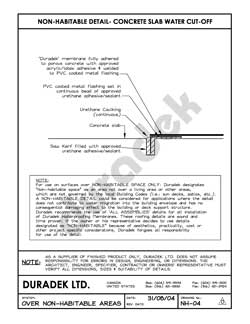

Non-habitable NH-04 – Concrete Slab Water Cutoff: PVC membrane on porous concrete with flashing set in urethane adhesive over non-habitable space.

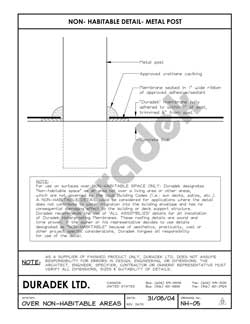

Non-habitable NH-05 – Metal Post: PVC membrane on concrete slab with metal post over non-habitable space.

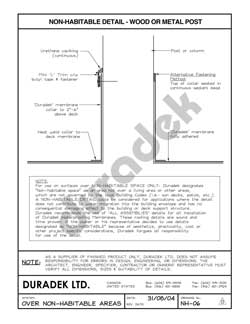

Non-habitable NH-06 – Wood or Metal Post: wood or metal post detail with PVC membrane collar on post or column with option of sealant or mini L-trim over non-habitable space.

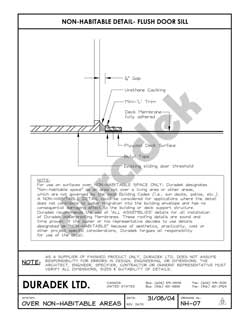

Non-habitable NH-07 – Flush Door Sill: PVC membrane fully adhered to flush door sill with mini L-trim and urethane caulking over non-habitable space.

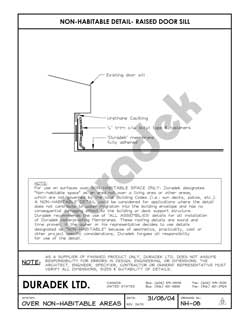

Non-habitable NH-08 – Raised Door Sill: PVC membrane fully adhered up to existing door sill and secured with L-Trim and urethane caulking over non-habitable space.

Duradek Detail Drawings – Drains

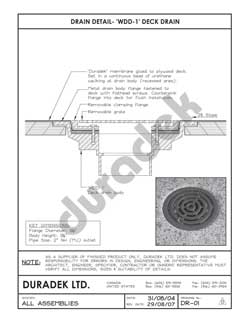

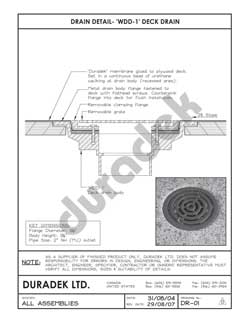

Drain Detail DR-01 – “WDD-1” Deck Drain: counter-sunk drain over PVC membrane with removable grate.

Drain Detail DR-02 – PVC Coated Deck Drain: counter-sunk PVC coated drain with membrane hot welded to drain body flange and into bowl.

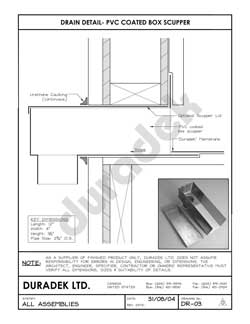

Drain Detail DR-03 – PVC Coated Box Scupper: PVC coated box scupper with optional lid where membrane is heat welded to scupper.

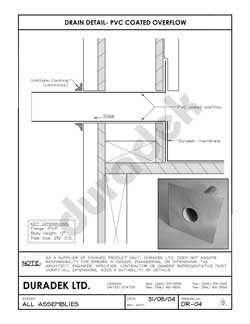

Drain Detail DR-04 – PVC Coated Overflow: PVC coated overflow drain for vertical walls where membrane is heat welded to drain surface.

Duradek membranes are installed by factory trained technicians, world-wide, which provides for consistency of detailing and waterproofing assurances.

More Installation Details for PVC Membrane Deck and Flat Roof Waterproofing

Access Duradek’s Architectural Resources for everything you need to design, specify and build exceptional outdoor living space with Duradek PVC Membranes.

Resources You Can Take With You

Access Duradek’s Architectural Resources for everything you need to design, specify and build exceptional outdoor living space with Duradek PVC Membranes.

- Full collection of Duradek CAD Drawings and BIM

- Substrate requirements and edge trim details

- 3-Part Specifications

- Testing evaluation reports and approvals

- AIA CES course

- Leeds Credit information

- Safety Data Sheets (SDS)

For Quick Access to all of these resources and more, download our Duradek Architectural Resources – Division 7 Quick Links pdf.

Continuing Education

For AEC professionals who would like to learn more, check out our AIA-CES registered online course, Walkable PVC Roof Deck Membranes hosted on AEC Daily.