USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Choosing a Waterproof Membrane for Your Deck

PVC membranes have earned the reputation of being a reliable, low-maintenance deck waterproofing solution. Duradek, the industry’s leader in PVC waterproofing introduced the popular use of this single-ply, walkable waterproof membrane nearly 40 years ago and still today continues to perform ongoing product testing to ensure performance and compatibility with other building products.

When professionally installed, PVC’s waterproofing performance extends well beyond most manufacturers’ warranties. Yet the quest for a “better, longer-lasting, newer” topcoat or film continues. While the concept is great, so far the end results on this pursuit have not been very successful.

Duradek has considered this innovation, but initial production with available technology was never able to provide the desired results; therefore Duradek chose not to offer a product they could not be completely confident in.

Others manufacturers may have gotten carried away with pushing a great idea forward before the manufacturing technology was able to support their exciting new product innovation with the performance results they desired. When these great ‘new and improved’ products are released into the market before being properly tested for long-term results, it is the homeowner who pays the price of research and development. (see our post from May 8th “When Choosing a Building Product, ‘New’ Does Not Always Mean Better“)

Deck Surfaces – Keeping Up Appearances

Not all products require the same kind of research and development. Deck building products are continually exposed to things like UV rays and moisture – two things that all new decking products are expected to withstand and should be tested to.

1999 – New Product Innovation: Clear Coat on PVC Membrane

This PVC membrane manufacturer may have not considered long-term testing, but Duradek did. They decided to put this ‘new’ vinyl to the test along with Duradek’s vinyl and the results are pretty evident in the images below. These images show the result of the ASTM G90 Accelerated Weather Test Method which is a widely used accelerated weathering test method.

This company was forced to remove vinyl from their product offerings and to the best of our knowledge, no warranty claims were honored.

2013 – New Product Innovation: Clear Coat on PVC Membrane

Once again a PVC membrane manufacturer who was excited to offer their customers a durable product by incorporating a clear top coat may have been too eager to get this ‘new’ innovation into the marketplace.

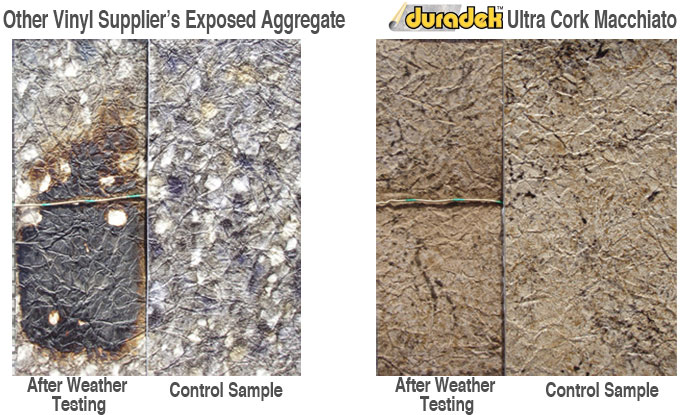

Duradek took a single random sample of this competitor’s vinyl and put it to the test against Duradek’s vinyl membrane. Accelerated weathering tests were performed by a third-party testing agency, Atlas Material Testing in Phoenix, Arizona. The testing was performed to the ASTM G90 (Standard Practice for Performing Accelerated Outdoor Weathering of Non-Metallic Materials Using Concentrated Natural Sunlight).

Tested side-by-side in the same conditions over a 9 month period, the results show a dramatic difference in how the two products stood up to the extended UV exposure.

While Duradek agrees that the concept of a clear top coat over PVC vinyl to extend the esthetic longevity is a great idea in theory, until the technology to produce this feature can be PROVEN to have lasting, long-term performance results, Duradek will not risk introducing an inferior product into the market and will continue to provide the same reliable product that has been successfully installed on over 100 million square feet of decks throughout North America.