USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Floating Deck Systems

Floating Deck Systems Waterproofed with Duradek’s Plazadek System

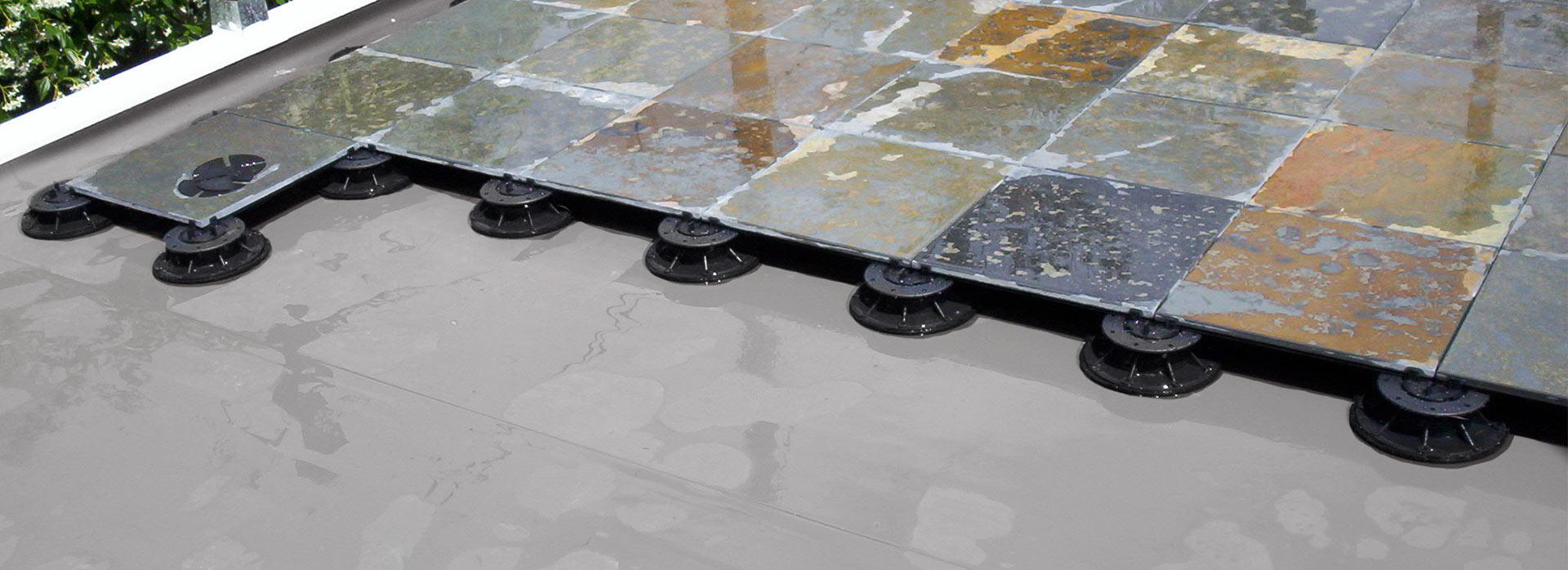

Floating deck systems are decking projects where the waterproofing component is not the finished pedestrian traffic surface, and a separate wear surface is applied over top.

The Plazadek System is an application of Duradek Ultra Vinyl specifically for use in floating deck applications using pavers, duckboards, or other wear surfaces. The 60 mil product is 25% thicker than what is required for roofing membranes on commercial buildings (48 mil) and therefore capable of handling almost any abuse it would be subjected to over its lifetime.

Pavers, tiles, plank boards, and other types of wear surfaces are not waterproof on their own. When waterproofing is required under the wear surface it is sometimes referred to as a Protected Deck or Roof Deck System. In the past, builders have relied on traditional roofing products to waterproof below the wear surface, but these solutions are not always ideal for roof decks, particularly in wood frame construction.

Duradek’s experience in the waterproofing of surfaces designed for leisure living and pedestrian traffic has shown us time and time again that the application of pedestrian roofing membranes requires details and a skill set beyond just keeping the water out. Deck and balcony waterproofing details are far more complicated than basic roofing. It requires finishing around doors, drains, pillars, railings, stairs, and many different types of siding and tie-ins to other roofing products.

Compare waterproofing options for protected deck and roof deck systems.

In addition to the proven performance of our waterproofing membrane, the primary benefit of Duradek’s Plazadek System is the trained applicators who install the material. Duradek will not sell waterproofing products to any company whose installers have not been trained. The typical details those installers work with every day on decks and balconies are just as important for decks covered with pavers or duckboards.

With Duradek vinyl doing the waterproofing job under your Floating Deck System, you have durable, long-lasting waterproof protection for a pedestrian deck or flat roof deck that protects the structure from moisture penetration.

Floating Roof Deck Considerations

A floating roof deck system requires an assembly with multiple components. There are three main components to a floating roof deck assembly.

- Waterproofing – waterproof protection of the building is the main priority, particularly in roof decks over living space.

- Wear Surface – choose a wear surface that is appropriate for your pedestrian traffic needs and aesthetic preferences.

- Separation Layer – how the wear surface is applied over the waterproofing component. This is an important component of both pedestal systems and direct application systems.

Lifecycle and Maintenance Requirements for the Plazadek System

Duradek PVC membranes have a long life cycle with no maintenance requirements for their waterproof performance. Duradek’s Plazadek system for a floating deck assembly comes with a 10-year warranty, however, the waterproof performance can last much longer. Because of Duradek’s excellent elasticity, it will expand and contract with extreme temperature variations and will never crack or chip.

However, you may have surface maintenance depending on the wear surface you choose. Concrete or stone pavers will require little maintenance while Ipe wood panels under high UV exposure would need treatment every 6 – 24 months to maintain their rich appearance.

Other Considerations in Building a Floating Roof Deck System

In addition to the maintenance of the wear surface, before you begin planning for a floating roof deck system, you need to consider the height and the weight that the assembly will add to the deck.

Floating Roof Deck Height Considerations – Be sure to account for enough clearance for door openings. Overlays will typically add a minimum of 3 inches to the height of the assembly.

Floating Roof Deck Weight Considerations – Overlays dead weight can be substantial. The structure must be engineered to accept the weight of the system you are considering.

Approximate weight of overlays:

- Wood Deck Panels 5 – 10 psf

- Concrete Pavers: 15 – 25 psf

- Interlocking Stone: 20 – 30 psf

- Poured Concrete: 20 – 30 psf or more

- Composite products are usually lighter

Plazadek System Note

The Plazadek System with Duradek Ultra Membranes requires a separation layer or use of pedestals to support heavy wear surfaces.

Heavy wear surfaces like concrete pavers, interlocking stone, or poured concrete are not to be placed directly on the Duradek Ultra Membrane due to friction and/or risk of puncture.

Failure to include a separation layer with stone or concrete assemblies will void the warranty.