USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Builders Resource Center

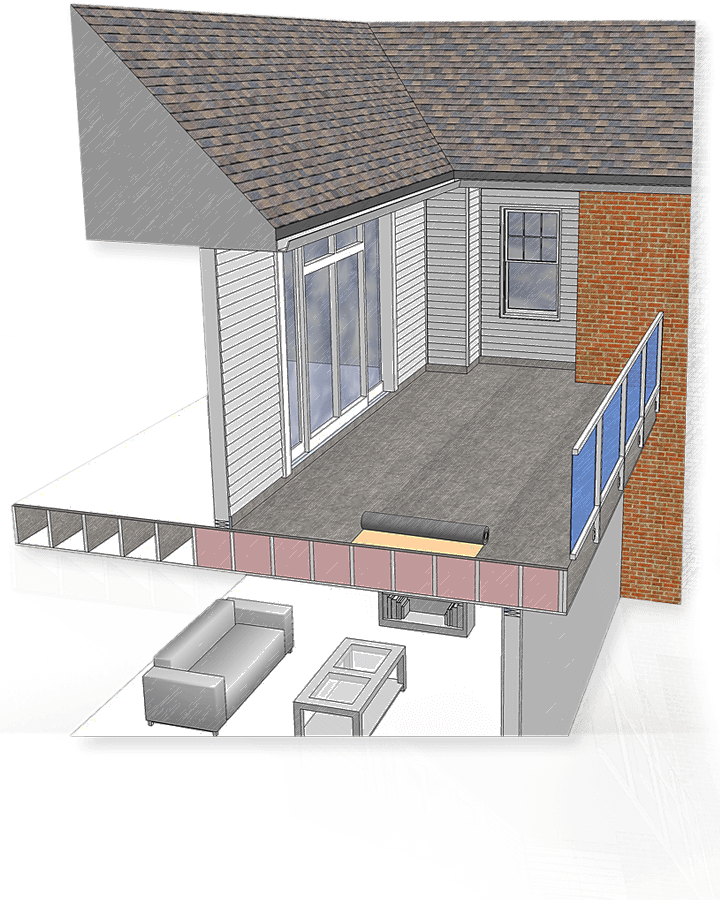

For a successful Duradek installation, planning starts well before the membrane is applied. The following considerations are critical to ensuring long-term waterproofing performance. Our Builders Resource Center provides everything you need to specify, design, and prepare your job site efficiently.

With over 30 years of trust from industry leaders like Toll Brothers, Pulte Homes, Ryan Homes, Stanley Martin Homes, DR Horton Homes, Khov Homes, and Richmond Homes, Duradek delivers proven waterproofing solutions for decks, balconies, and flat roof decks. Our commitment to supporting the builder community ensures projects are done right the first time, protecting your work and your reputation. Explore the essential pre-installation considerations and best practices to integrate Duradek seamlessly into your next build.

Important Considerations Before Installation

A successful Duradek installation depends on proper preparation and adherence to best practices. Before installation, consider these key factors:

Substrate Preparation: A properly prepared subsurface is essential for a successful installation. See Techtalk 126 US | CAN for recommendations.

Proper Slope: A minimum 2% slope is recommended for the deck substrate to eliminate ponding water.

Penetrations: Any deck penetrations, such as rail attachments, must be sealed to prevent moisture from compromising the waterproofing system.

Material Compatibility: To prevent chemical reactions and corrosion, avoid direct contact between Duradek and incompatible materials.

By following these guidelines, you can ensure a high-quality installation that stands up to the elements and provides long-term waterproof protection. Also see our Best Practice Builders Guide above for more information.

Duradek Site Supervisor Training

The Duradek Site Supervisor Training is designed to give builders and foremen the knowledge they need to confidently oversee projects involving Duradek. Covering essential requirements and installation methods, this course ensures you understand what goes into a successful vinyl membrane installation.

Whether you’re overseeing projects or managing crews, this training ensures you understand the ins and outs of vinyl membrane installation, maintain quality standards, and keep every project involving Duradek on track.

Please fill out the form below to request a date for Duradek to present this course to you and/or your organization.

Supervisory Course Request

Technical Support and Builder Resources

Testing and Approvals

Duradek’s vinyl decking products have undergone rigorous testing to meet and exceed industry standards for walkable PVC membranes.

Key approvals include:

- Approvals in the USA: ICC-ES Evaluation Report, FBC (Florida Building Code) Approvals, ASTM 4434 Type 2 Certifications.

- Approvals in Canada: CCMC (Canadian Construction Materials Centre) Type 3 Certification, CGSB (Canadian General Standards Board) 37.3-94 Certification.

- Third-Party Testing: Independent evaluations ensure compliance with North American building codes, verifying the safety and reliability of Duradek products.

Duradek meets all relevant building code approvals and testing standards. Do the alternatives? Check the list and compare!

Other technical resources:

Installation Sequencing and Details

Vinyl deck installation details developed through Duradek’s 50+ years of waterproofing experience come with unsurpassed installation techniques for moisture management. The integration of the membrane into the building envelope brings complete waterproof assurance. Learn more about Installation Sequencing here.

Good, Better and Best Deck Waterproofing Details

There are Good, Better, and Best methods of achieving the desired result for your project. The methods your contractor chooses can be influenced by building code requirements, your budget restrictions, or your insistence (it is your project, after all). Your professional Duradek contractor will always recommend the best methods to ensure reliable waterproof protection so you can be confident that you receive the best results for your deck. Learn more about reliable waterproofing details here.

Design Resources

From residential and commercial projects, to large-scale developments, these real-world examples highlight the versatility, durability, and performance of Duradek vinyl decking. Browse through these visual resources for inspiration, installation insights, and alternative ideas on how Duradek can enhance your next project.

FAQs

Have questions? Duradek has answers.

Additional Support

If you need assistance with your Duradek projects, we’re here to help.

Contact us to find a dealer, connect with our sales team, or get expert advice from technical support.