USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Powder Coating

The Process that Defies the Elements

Powder coating is an advanced method of applying a decorative and protective finish to a wide range of industrial and consumer products. It is used on many metal items that are exposed to the weather. As a finish for your railing and fencing needs, it is the best method to ensure durability, weather resistance and color retention.

Powder coating is an advanced method of applying a decorative and protective finish to a wide range of industrial and consumer products. It is used on many metal items that are exposed to the weather. As a finish for your railing and fencing needs, it is the best method to ensure durability, weather resistance and color retention.

Benefits of Powder Coating

- Environmental Compliance – No VOCs (Volatile Organic Compounds) used

- Corrosion Resistant Finish – Powder is baked into the aluminum creating a durable finish

- No chipping

- Salt water and UV resistant

- Virtually maintenance free – no yearly painting required

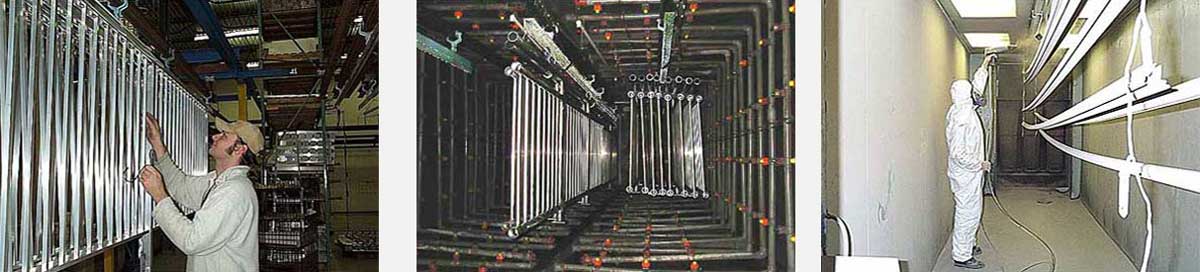

The Durarail Powder Coating Process

Durarail’s coating is applied in a four stage, cabinet style (spray nozzle) process.

Stage 1

The aluminum material is sprayed with an alkaline solution pre-treatment to prepare the surface. This is designed to clean the substrate of mixed metals, oils, and contaminants prior to powder coating.

Stage 2

A seal coat is then applied for the coating process. This seal coating process is a chrome-free, non-phosphate liquid coating chemical used on aluminum and zinc alloys. A clear, nearly colorless chemical is applied and dried in place. This coating has excellent paint bonding properties and adds additional substrate protection.

Stage 3

Completely dry and contaminant-free, the rail sections receive an electrical charge (negative) and sprayed with powder. The powder receives a positive electrical charge and literally “wraps” itself onto every bit of the exposed metal. This is an environmentally friendly system as no solvents are used.

Stage 4

The powder coated components are then baked in a 400° F oven for superior adhesion and a consistent thickness (approx. 2 to 4 mils). The polyester material (TGIC) is UV resistant and will not peel, flake or blister. As it ages, it can be buffed back to like-new condition with a cut polish.

Durarail Powder Coating Performance Requirements

Durarail’s powder coating facility meets the American Architectural Manufacturers Association (AAMA) performance requirements for the long-term durability of organic coatings on aluminum extrusions and panels used in high quality aluminum windows, doors and railings.

Durarail meets AAMA 2603 and 2604 specifications. Upon request, the powder coating can be upgraded to meet AAMA 2605 specifications.