USA: 1-800-338-3568 | CANADA: 1-866-591-5594

Substrate & Edge Trims

Compatibility

Duradek membranes are PVC based therefore some other products may react chemically when they come into contact with the membranes. The technical bulletins below address some of these issues and provide options for products that are chemically compatible.

Techtalk #152: Duradek membranes are not compatible with Bitumen based products, December 2010

Substrate and Edge Trim Considerations for Vinyl Decking

Duradek provides an installed waterproofing system complete with edge trims for vinyl decking. Our Trained and Authorized Installers are well versed in general waterproofing principles and can recommend the Good, Better and Best detail options for your decking project.

The recommendations from your Duradek Installer would be determined by the specific project parameters such as new construction versus renovation work, details unique to the project, budget considerations, or by a preference of the look or function of the deck.

Please see the three substrate recommendations and four edge trim options available for a Duradek vinyl membrane installation below. Then, reach out to your local Duradek Installer to discuss which option is best for your project and your budget.

Vinyl Decking Substrate Requirements

The first step towards a completely waterproofed vinyl deck is a properly prepared substrate. Duradek must be installed on a flat, smooth surface; including untreated plywood, concrete, and sealed or coated surfaces.

Resources for details on substrate preparation:

Techtalk #126 CAN: Plywood Sheathing and Deck Construction Recommendations, Rev October 2018

Techtalk #126 US: Plywood Sheathing and Deck Construction Recommendations, Rev October 2018

Techtalk #126 Supplement: Plywood Requirements Supplement, Rev October 2018

Techtalk #140: Duradek Application to Concrete, May 2013

Techtalk #161: Duradek Application to Sealed or Coated Surfaces, March 2012

Edge Trims and Waterproofing Details for Vinyl Decking

Your Duradek installer will recommend the best edge trim and other waterproofing details for your project. Recommendations are based on best water routing management and for the finished look you desire. Duradek provides 4 options of edge trims and a selection of water routing accessories.

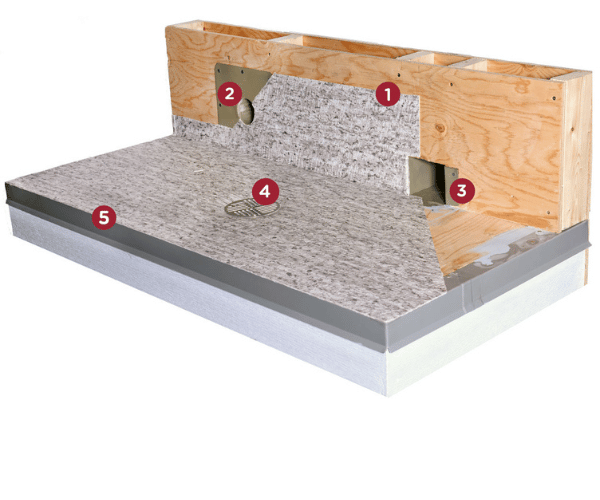

PVC Coated Metal Edge Trim and Water Routing Accessories

- Vinyl extended up the wall 6 to 8 inches (as per local code)

- Vinyl welded to PVC-coated overflow drain

- Vinyl welded to PVC-coated box scupper

- Vinyl welded to PVC-coated drain

- Vinyl welded to PVC-coated flashing

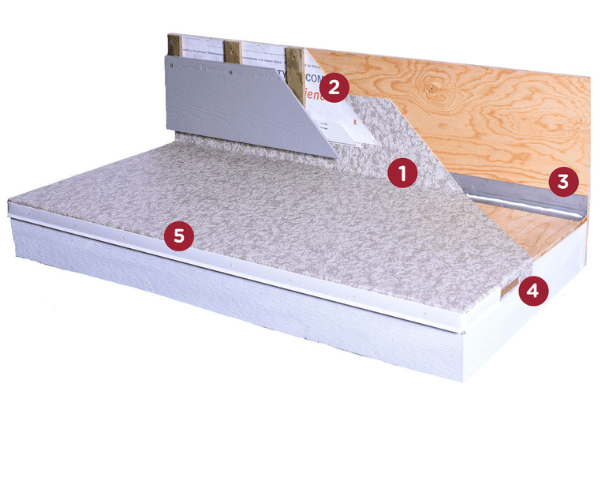

L-Trim Edge Trim and Installation Sequencing Details

- Vinyl extended up the wall 6 to 8 inches (as per local code)

- Vinyl overlapped by building paper and exterior finish

- Caulking in 90° corner

- Butyl tape behind L-Trim

- L-trim secures (with screws or nails) vinyl on the outside. (Inside edges optional)

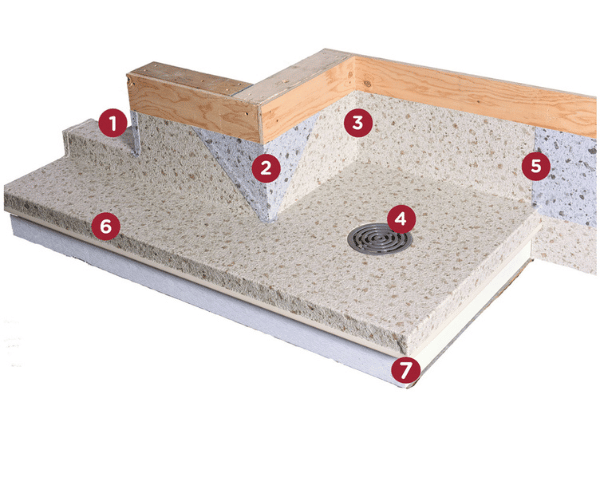

PVC Clip Edge Trim with Corner, Door & Drain Detail

- Vinyl wrapped door threshold

- Outside front corner relieved and patch welded

- Inside back corner folded and welded, not cut

- Roof-quality drain with clamping ring holds the vinyl in place (with caulking)

- Deck to wall intersection (with optional water diverter)

- Galvanized flashing with PVC clip holds the vinyl in place

- Outside front corner folded and welded, not cut

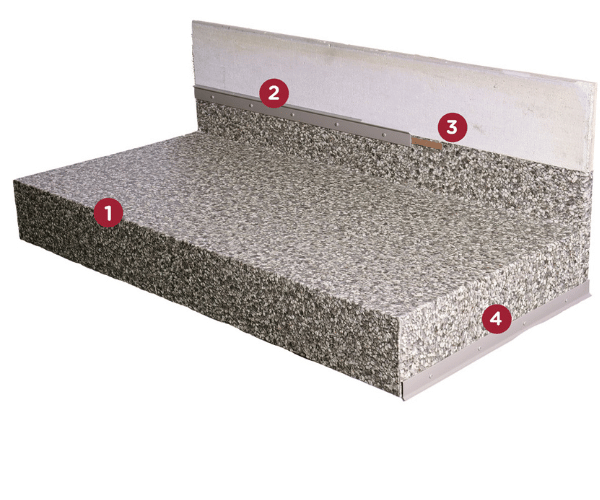

Fascia Fully Wrapped and L-Trim Option Details

- Full wrap over fascia

- Inverted “L” trim with caulking (Gum Lip)

- Butyl tape as a sealant (screw seals itself with compression)

- “L” trim with stainless steel color matched screws